Digital technology is widely accepted as a necessary part of driving improved supply chain efficiency and effectiveness. But some business leaders think it could go a step further, suggesting the technology could propel not only greater productivity, but help craft an autonomous supply chain able to identify, forecast and fix problems on its own.

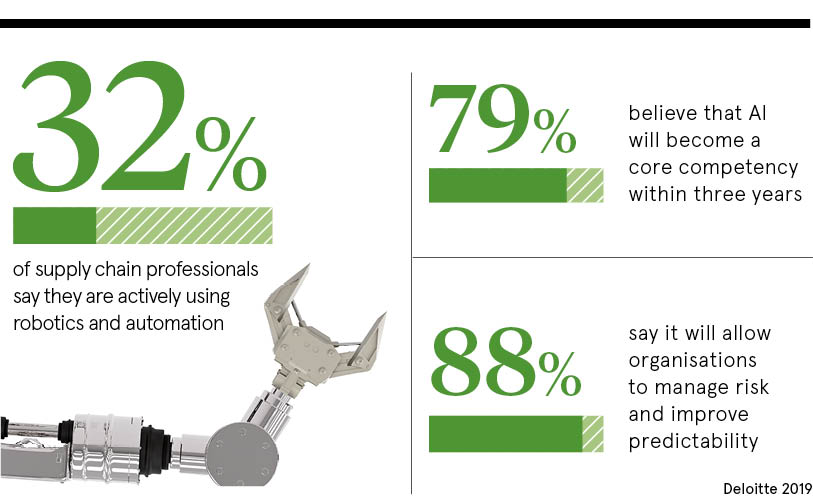

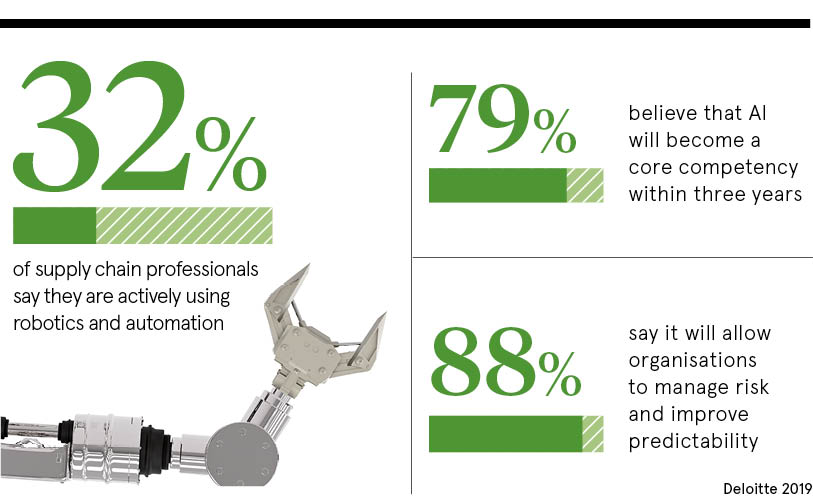

A combination of technologies, from artificial intelligence (AI) and machine-learning to digital twins and cloud computing, have made it increasingly possible for end-to-end supply chains to make decisions without the need for human intervention. These technologies, which appear to have all the right ingredients for the formation of an autonomous supply chain, are slowly permeating the market.

Ocado is using advanced autonomous supply chain processes to help make accurate predictions. The online supermarket uses forecasting based on machine-learning to predict outbound demand for more than 50,000 different products.

“This means we can generate exceptionally accurate projections with which we place orders with suppliers,” says James Gralton, engineering director of logistics and supply chain at Ocado Technology. “We currently generate over 20 million forecasts each day. This helps us to react rapidly to a multitude of common and exceptional supply issues.”

Why is supply chain autonomy important?

Autonomy is not just a handy tool for improving supply chain efficiency and effectiveness. It’s a logical and necessary next step for an industry that continues to grow in complexity. Without a certain level of autonomy, traditional supply chains would struggle to handle growing inventories and fail to keep up with the equally challenging shift of consumer demand.

The key is deciding in which areas of the supply chain to develop autonomy to create the most economic value

“As global inventories look set to double between 2015 and 2020, logistics companies and customers need to leverage these technologies to reduce costs and increase throughput traditional warehouses are not able to handle,” explains Marcus Würker, chief information officer, UK and Ireland, at DHL Supply Chain.

An autonomous supply chain can identify patterns the naked eye would never spot. This gives businesses the best chance of responding to these pressures with accuracy and decisiveness.

Self-governing supply chains also have the capacity to help tackle one of the industry’s biggest concerns: sustainability.

“There’s an increasing demand for less plastic and preservatives to enter the supply chain, which ultimately causes challenges when it comes to making sure goods are delivered in a good state,” says Phil Skipper, head of business development at Vodafone Business.

“This is where automation can have a big impact, helping ensure goods move through the chain to reach their destination efficiently and in top condition. For example, the internet of things can be used to measure factors like the temperature and humidity of perishable goods, allowing businesses handling them to quickly step in if there is a risk to the condition of the items.”

Is end-to-end autonomy possible?

However, while end-to-end autonomy is in theory feasible and businesses are beginning to implement autonomous processes, the industry is still in the early stages of deployment. Whether or not the industry can integrate digital technologies and establish self-governing systems throughout the supply chain is still up for debate.

“We’re still at the beginning of our journey towards an automated supply chain, but it’s clear robotics and AI will shift paradigms over the next few decades,” says Mr Würker. “Operations will become predictive, more processes and transport will become automated, and a greater degree of personalisation of services will be possible, resulting in a far superior customer and end-user experience.”

He anticipates advancements in AI will magnify the capabilities of robots and allow for important developments in computer vision for dimensioning and object identification, while machine-learning will improve prediction and planning.

Antony Lovell, vice president of applications at Vuealta, says: “While the technologies on offer are developing at a rapid pace, we are quite a long way from seeing autonomy in the supply chain.

“Supply chain and demand planners are trying to predict product demand based on old, unstructured data which can takes weeks to collect. They often work in cumbersome and error-prone manual spreadsheets or outdated systems, sometimes multiple versions of each.”

Autonomous supply chain not the only goal

But according to Wayne Snyder, head of retail strategy at JDA, although achieving an autonomous supply chain can appear an impossible task at first, the good news is even if a business has to navigate a change-resistant culture, or uses technologies that lack the right processing capabilities to collect data, with the right tools and strategy it is within grasp.

“Total autonomy is unlikely,” he says. “There will always be times when the computer needs human oversight, for example when the data identifies a scenario it has never experienced. However, a near-autonomous supply chain will have been achieved when businesses are able to trust technology to identify disruption and take actions.”

Mr Snyder says these actions will regularly be reviewed to understand their success, both by computer and by humans, to improve performance and ensure the supply chain acts optimally with immediacy and decisiveness. Results could be completely transformational, as alongside short-term problem-solving, autonomous supply chains could provide longer-term learnt recommendations to enable businesses to stay ahead of the curve.

“Total autonomy may not be possible, nor desirable, but as long as there is value to be had for retailers and consumers, there is more to be done,” Mr Gralton at Ocado Technology concludes. “The key is deciding in which areas of the supply chain to develop autonomy to create the most economic value.”

Supply chain autonomy could transform the industry. Technology is available; it just needs to be harnessed.

Why is supply chain autonomy important?

Is end-to-end autonomy possible?